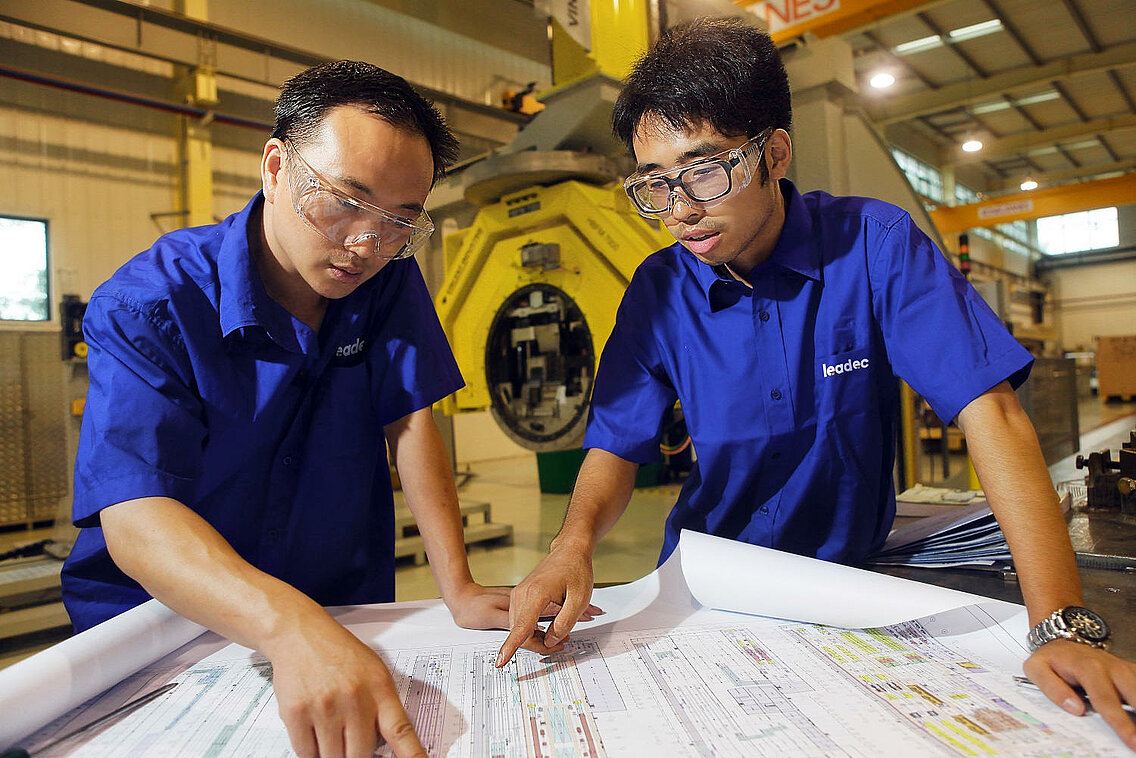

Dirt and technical facilities are not compatible. Leadec has been cleaning industrial facilities for nearly 60 years now – especially paint lines. That’s why we know exactly what care today’s machines and systems need. Because experience pays off.

Relocation

The relocation of production units or entire production facilities is one of the most challenging areas of factory organization. For that reason Leadec draws on its entire range of planning, logistics, and human resources services to ensure that every relocation project is a thorough success.